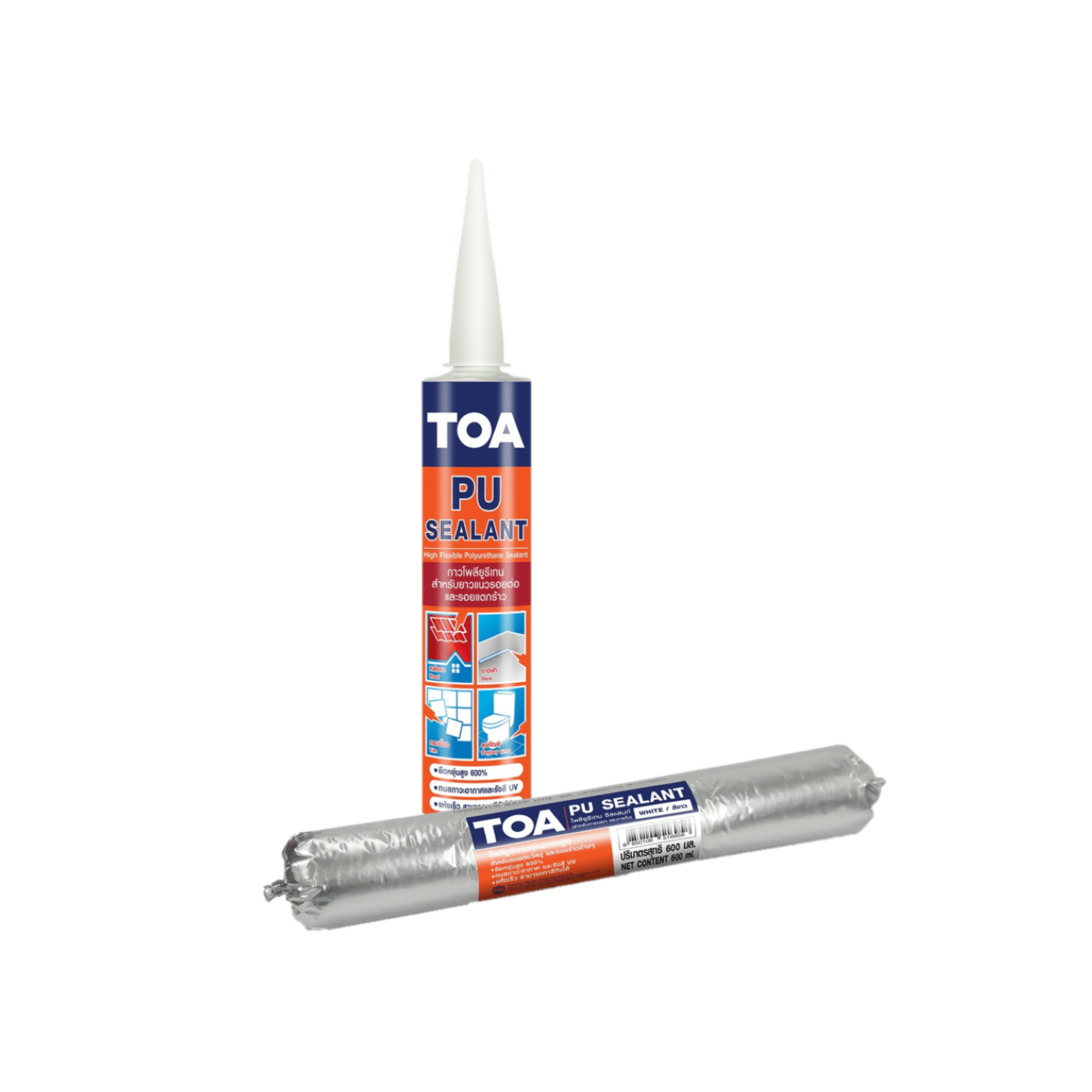

Construction chemicals are nothing but chemical compounds that are used in building structures. Polymers are one of the most significant type of materials and are present in the formation of almost every construction chemical.

Construction chemicals are actually several types of chemicals used to reinforce each other. Site goodwill or construction materials of cement or concrete, etc. at the time of construction was a golden rule.

Copyright © 2022-23 Accurate Enterprise. All Rights Reserved.